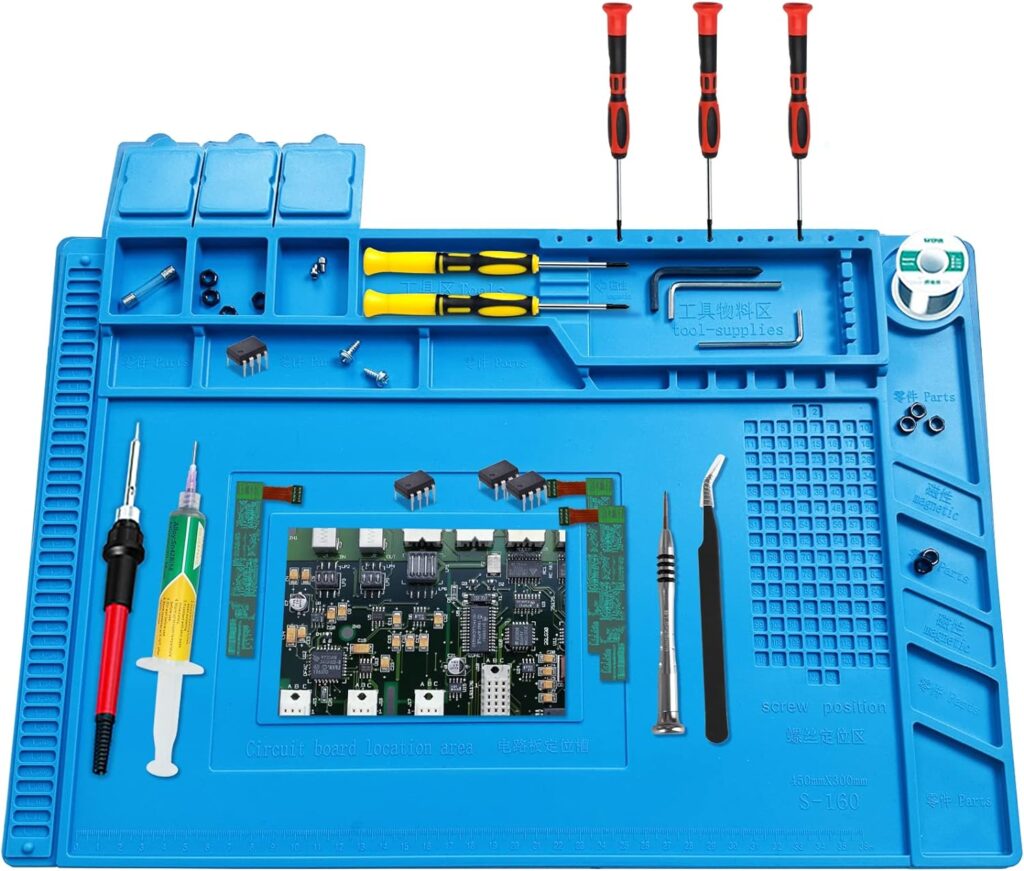

The function of a silicone soldering mat, abbreviated as “R”, is primarily to provide a safe and convenient work surface for soldering and other electronic assembly tasks. Here are some key functions and features of silicone soldering mats:

- Heat Resistance: Silicone soldering mats are designed to withstand high temperatures encountered during soldering without melting or deforming. This property protects the underlying workbench or table from heat damage.

- Insulation: The silicone material acts as an insulator, preventing heat transfer to the surface beneath the mat. This helps protect sensitive electronic components and prevents damage to the work area.

- Non-slip Surface: Silicone soldering mats often have a textured surface that provides grip, preventing tools, components, and small parts from sliding around during soldering tasks.

- Built-in Compartments and Slots: Many silicone soldering mats feature built-in compartments, slots, and grooves to hold tools, soldering irons, components, and small parts securely in place. This organization helps keep the workspace tidy and prevents loss of components.

- Non-stick Properties: Silicone mats are typically non-stick, making it easier to clean off solder residues, flux, and other debris after completing soldering projects. This facilitates maintenance and prolongs the lifespan of the mat.

Overall, silicone soldering mats provide a safe, insulated, and organized work surface for soldering and electronic assembly, enhancing efficiency and protecting both the user and the equipment.